Overview

Our process services help you move online quickly, eliminating leaks and other start-up problems and delivering your product purity specifications. We offer engineered solutions for pre-commissioning, commissioning, and maintenance shutdowns with specialized services for the oil and gas, power generation, metals and mining, and other process industries.

Our integrated package of services includes nitrogen services: purging, helium leak testing, bolt tensioning and torquing, system cooldowns; cleaning services: lube-oil flushing, chemical cleaning, retrojetting, high-velocity flushing; and drying using either air, nitrogen, or vacuum. We can package these services together to manage the entire pre-commissioning process. This optimizes the utilization of people and equipment, reducing overall cost, decreasing time to system start-up. For plant turnaround, our services minimize outage time while improving plant efficiency.

Nitrogen services

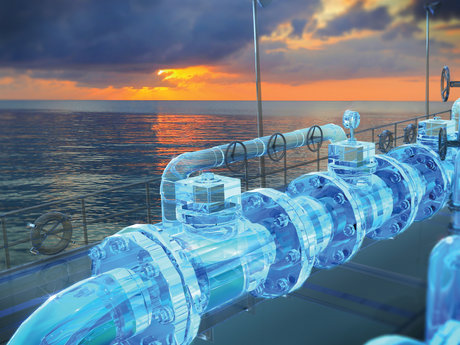

Baker Hughes’s nitrogen services reduce project time, risk, and cost with efficient nitrogen usage onshore or offshore during new construction or turnarounds. We support projects in oil and gas production, LNG, refining, petrochemical, power generation. Our services ensure you have a clean, dry, leak-free, and inert unit ready to safely receive product the first time, according to industry standards. If temperature is an issue, we can precool or preheat your piping and vessels to the required level.

Testing cleaning and drying services

As part of your plant pre-commissioning or turnaround, our leak testing, cleaning, and drying expertise means a faster start-up with greater operating efficiency.

Integrated pre-commissioning services

无论你是开发一个新建站点,依斯攀ding a refinery, building process modules in a construction yard or hooking up an offshore platform, our integrated pre-commissioning services enable on-schedule, uninterrupted plant start-up on your new construction project. Our packaged services reduce plant downtime, minimize cost, and HSE risk with a one-stop solution driving greater efficiency.

Integrated turnaround services

Our turnaround services provide a one stop solution to reduce cost, plant downtime, and HSE risk. Engineered industrial nitrogen services and chemical decontamination expertise help deliver shorter shutdowns and faster clearing

Mobile flaring services

Mobile flaring services reduce emissions whether you’re decommissioning a pipeline, degassing a tank, or removing residual product in a plant turnaround. Our clean-burn variable tip flare technology ensures complete combustion of your waste materials. Clean-burn prevents the release of unconverted hydrocarbon materials, undesirable by-products and solid carbon deposits, ensuring emissions concentrations to reduced significantly below local legislative limits.

Temporary fuel gas and LNG Supply

Our temporary fuel gas and LNG supply service keeps gas flowing to your customers during outages, ensuring you meet your contractual obligations. Whether a supply shortage in a remote location, planned maintenance work, or an unexpected shutdown, we offer tailored support. Vaporized LNG is delivered at precisely controlled pressure, temperature, and flow rate for an uninterrupted supply. We can blend other materials to ensure calorific value and molecular weights match your specifications. We can also fuel your turbines, gas compressors, and power generation systems while in the construction yard, allowing you to troubleshoot and commission the units before shipping offshore.

Refinery coke cutting

Our refinery coke cutting service ensures continuous coke cutting for a wide range of flow and pressure requirements with our unlimited global pumping equipment fleet.

Enhanced oil recovery

Enhanced oil recovery services help maximize your ROI without committing to CAPEX. Our temporary equipment packages help you to determine if the chosen method of reservoir flooding will respond as predicted before investing in a permanent facility.

机械联合完整性(螺栓和加工)

无论你是开发一个新建站点,依斯攀ding a refinery, building process modules in a construction yard or hooking up an offshore platform our Mechanical Joint Integrity offering including our Electronic flange management system can be key driver to realizing a leak free start up.

Mechanical joint integrity service is offered as a standalone offering or as a part of integrated services.