Moisture in liquid benzene feed stock

Moisture is measured in liquid benzene used as a feedstock in the manufacture of styrene polymer.

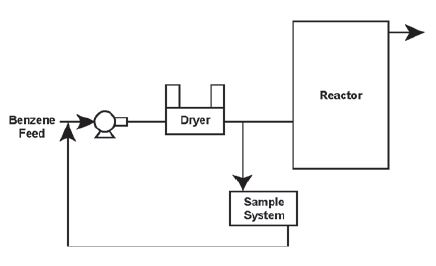

Dry benzene enters a reactor containing chlorinated compounds. If the upstream dryers are not operating properly, moisture in the benzene promotes hydrochloric acid formation causing acid corrosion of the reactor and process lines.

In the past, moisture measurement in the benzene feed stock was performed in the laboratory using the Karl Fischer analysis method. This required meticulous sampling techniques and a laboratory chemist proficient in making this measurement. This method is not continuous, thus a dryer failure might not be noticed until product has been wasted.

The reactor feed line is a stream of benzene feed stock that is flowing into a styrene reaction kettle. A sensor is inserted into a sample system installed just upstream of the reactor off the reactor feed line. The moisture content of the benzene is continuously monitored as it passes into the reactor. The ppmw moisture content is calculated from dew point, stream temperature, and known saturation values of benzene.

Benefits: The advantages of using the Panametrics aluminum oxide moisture sensor are: • by permanently installing a Panametrics aluminum oxide hygrometer in the benzene feed stock, expensive plant maintenance (involving downtime and repairs due to corrosion) is minimized, • the sensor can be installed as a transmitter, or • a single multi-channel analyzer can accept inputs from multiple sensors.

Moisture Content Range: 1 to 100 ppmw Dew Point Range: -30° to 20°C (-22° to 68°F) Operating Temperature: 25°C (77°F) Operating Pressure: 14.7 psia (101.3 kPa)

Learn more about Panametrics' hygrometers