Orbit 60 Series Update: Now Available to Quote!

Bently Nevada is excited to announceOrbit 60is available to quote (ATQ) as of early April. Our teams are actively working with customers on upgrade opportunities, new applications, and large global projects to position Orbit 60’s innovative design. The architecture of Orbit 60 provides significant overall project cost savings from field wiring deployment costs with our innovative bridging design, simplified network architecture from built-in cyber security and reduction in control room space with a smaller footprint to name a few. This article will focus on key areas of deployment cost savings with the Orbit 60 architecture.

One of the most common asked questions is how long will 3500 be supported and evaluating what technology to align with on upcoming projects. The 3500 is our flagshipmachinery protection and monitoring platformwith over 86,000 installations globally, Bently Nevada acknowledges the significant investment our customers globally have made in this platform and we are committed to supporting the 3500 for many years to come. Bently Nevada has a strong history of supporting our products, when the 3500 was introduced into the marketplace in the mid 1990’s, we continued to support 3300 for nearly 20 years as customers had opportunities to align outages and migrate to the latest market standard. The Orbit 60 announcement is no different, we will continue to support 3500 in parallel as we roll out Orbit 60. Orbit 60 will be a feature rich product in release 1, therefore the choice is yours to continue with 3500 or explore the new Orbit 60 platform.

The most traditional deployment of 3500 is mounted in control rooms or instrument buildings with field wiring runs back to the machine. Occasionally their are limitations on field wiring lengths that need to be overcome or the choice becomes to field mount 3500 in specially designed enclosures for the environment. Either of these methods are perfectly acceptable and either 3500 or Orbit 60 can accommodate these scenario’s. However, Orbit 60 architecture provides a new concept to address field wiring costs and alternative deployment methods.

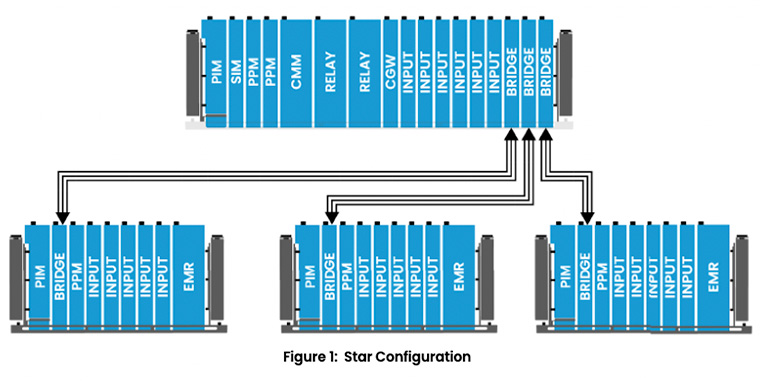

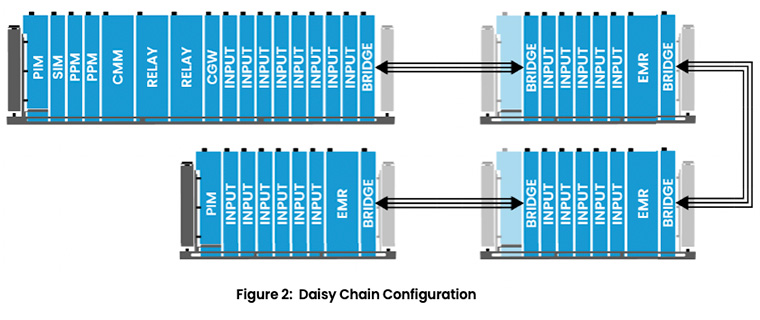

The Orbit 60 delivers a innovative one of a kind (patent pending) architecture to connect multiple systems together in release 1, whether you are sharing processing across multiple machines or aligning with the field I/O deployment to reduce installation costs. The bridging of Orbit 60 is not the same as other system to system connections you see today, all data from one system is replicated across all bridged systems at a very high speed, essentially extending the backplane across the plant for deployments for eithercondition monitoringand/or protection applications.

This architecture allows the user to keep the processing components of the system out of the elements in a safe environment, while having the I/O next to the machine. Industry standard Ethernet or fiber optic connectivity is used to connect the bridged systems, where lengths over a kilometer are now a reality, thus eliminating the field wiring length restrictions. This architecture is providing customers on average a 60% reduction in field wiring costs (electrical labor, conduit, wire and other materials) with the savings typically covering the investment of the hardware!

It does not stop there, there are several other advantages for bridging:

- No limitation to field wiring length, no longer a 1,000ft limitation

- Reduction in group loops/noise

- Triple connections on the bridge modules (all redundant) to provide confidence in protection applications

With the reduction in the foot print of Orbit 60 by 50% compared to 3500, customers are also achieving a significant reduction in cabinet space in the instrument rooms or control rooms. This coupled with remote I/O deployments as noted above where all I/O modules are in the field, we are seeing at least a 50% reduction in panel space allocation when compared to current deployments. The cabinet design becomes more simplistic as all field wiring is done remotely with the control room cabinets focused on relay outputs and connectivity to external devices (DCS/Control System, System 1 and display networks).

With foundational cyber security built-in every Orbit 60 system, several new architecture options are available to consider when connecting to your condition monitoring network. Orbit 60 will have built in latest encryption standards unlike any other system on the market today, in additional to segregation of condition monitoring and protection networks, network complexity can be simplified significantly. After several key customer engagements, we are noting network cost savings of up to 50% associated with Orbit 60.

Orbit 60 has consolidated our input monitors greatly, along with a common processor for all field inputs, customers are seeing a reduction of spare parts by 40% in the new Orbit 60 platform.

- 2019年秋季伊斯兰教纪元——公开披露和新产品uncement (ATD)

- Spring 2020 (April) - Available to quote (ATQ) fixed price proposals

- Spring 2021 (April) – Available to ship (ATS)

First customer pre-order received due to the enhanced cyber security of Orbit 60 in the Fall 2019! Just one of the key benefits from the Orbit 60 platform architecture based on the voice of our customer in the development of this next generation platform.

Bently Nevada Sales Manager- Power Industry

Our teams are excited to discuss Orbit 60 in more detail, we have multiple technical white papers available for a deeper dive into the following topics. Please reach out through the contact us link below to receive a copy and we will connect you with your local expert.

- Orbit 60 Series or 3500 Detailed Comparison- This document details the difference between Bently Nevada’s Orbit 60 Seriesmachinery protection systemand the 3500 system.

- Orbit 60 Data Security Condition Monitoring Module- This document is intended to describe how the Condition Monitoring Module in the Orbit 60 Series Monitoring System provides a secure solution with full high-resolution data to external networks without jeopardizing the operation of the protection functions.

- Orbit 60 Series Bridging Concepts- Bently Nevada introduces the concept of bridging with the Orbit 60 Series system architecture.

- Product Page

- Data Sheet

- Fact Sheet

- Product Video - Orbit 60 Teaser

- Product Video – Orbit 60 Full length

- Orbit 60 Series and System 1: Bloomberg TV:

- Houston Chronicle: Bently unveils the Orbit 60

- Turbo Machinery Magazine – Bently Nevada’s New Platform

A consolidated comparison is available on our website. In summary, we understand that the 3500 will still represent a great value for our customers who are not ready to fully leverage what the Orbit 60 can do. Rest assured, we are reaffirming our commitment to those customers and offering additional information to support.

Copyright 2020 Baker Hughes Company. All rights reserved. Baker Hughes provides this information on an “as is” basis for general information purposes. Baker Hughes does not make any representation as to the accuracy or completeness of the information and makes no warranties of any kind, specific, implied or oral, to the fullest extent permissible by law, including those of merchantability and fitness for a particular purpose or use. Baker Hughes hereby disclaims any and all liability for any direct, indirect, consequential or special damages, claims for lost profits, or third party claims arising from the use of the information, whether a claim is asserted in contract, tort, or otherwise. Baker Hughes reserves the right to make changes in specifications and features shown herein, or discontinue the product described at any time without notice or obligation. Contact your Baker Hughes representative for the most current information. The Baker Hughes logo, the Bently Nevada logo, and System 1 are trademarks of Baker Hughes Company.