Orbit 60 series update: the next generation of protection, condition monitoring & data integration

The excitement across the marketplace is in full swing with the announcement of Bently Nevada’s next generation condition monitoring, protection and data integration platform at three key events globally in September 2019.

Bently Nevada is well underway with alpha and beta testing partnerships across a wide variety of customers and applications worldwide. A key milestone was achieved, we accepted our first pre-order shortly after the announcement in late 2019 for Orbit 60 hardware, System 1 Software, and Services. The feedback has been extremely positive, aligning with our customers long term vision for a flexible and secure platform to be applied to all plant-wide machinery.

The Orbit 60 platform is complimentary to the broader Bently Nevada solutions portfolio, providing our valued customers with more flexible options for new projects, retrofits, and applications across the facility.

Many of the features in the Orbit 60 platform align with potential cost savings in key areas: Simplified network architecture, reduction of field wiring, increased sensor counts and multiple machines per installed system. Engineered and designed with the customer in mind, the Orbit 60 already has 18 new product design patents pending, leading the marketplace innovation for the next generation of protection, condition monitoring and secure data integration platform.

Bently Nevada’s flagship monitoring system, 3500, will continue to be supported in coming years and well into the future; the 3500 is currently in full product support status, with new features and functionality in development.

- Fall 2019 – Public disclosure and new product announcement (ATD)

- Spring 2020 (April) - Available to quote (ATQ) fixed price proposals

- Spring 2021 – Available to ship (ATS)

There will be a series of articles published around the Orbit 60 platform in future Orbit publications, focusing on showcasing unique aspects of the platform including:

Ranked as the #1 focus area around deploying new technology, and listed as a top priority by the vast majority of customers in our industry, Bently Nevada has designed cybersecurity into every Orbit 60 platform. The Orbit 60 system is designed to comply with IEC 62443-4-2, up to Security Level (SL) 4, a globally recognized Cyber Security standard. With segregation of protection and condition monitoring networks designed into each Orbit 60, there is no possibility for an unwanted user to breach a condition monitoring network and negatively impact the protection configuration.

The Orbit 60 platform embodies the best attributes of all the Bently Nevada portfolio together, allowing the system to be deployed on virtually all machines and applications. The modular nature of the platform allows for the configuration to be adapted to protection and/or condition monitoring only applications at a competitive price.

Large machine trains or clusters of plant-wide assets are no problem, with the ability to bring in any number of speed and Keyphasor signals, the options are endless on how Orbit 60 can be deployed. Orbit 60 is tailored for both journal and rolling element bearing (REB) applications, covering machines from high speed critical turbomachinery to plant-wide assets, such as pump, motor and fan applications.

During the in-depth research and discovery process with customers globally, a key message was the need to correlate data from all aspects of a process into one view. Our teams leveraged these operational insights to simplify the integration of process data and make this elegant solution a central design aspect of Orbit 60.

Utilizing the new design of the Communication Gateway (CGW) module in Orbit 60, bi-direction communication has been enhanced with retrieval of high-speed process data from a DCS, Control System or connected device. This allows Orbit 60 to perform state-based data filtering at the hardware level as well as providing a secure connection to send process data into System 1, enabling Bently Nevada Diagnostic HMI functionality.

轨道60 bri创新架构dge multiple bases together to develop a system that can be distributed in a daisy chain or star configuration. The bridge design replicates all data from one bridged base to the other, maintaining data resolution to achieve full system functionality across the distributed architecture. Whether you are looking to reduce field wiring costs by placing Orbit 60 I/O’s next to the machine or connecting multiple assets together with common processing and protection components back in a control room environment, the architecture provides full flexibility. With Orbit 60, field wiring distance limitations are a thing of the past.

With over 100x the processing power of the industry leading standard today, Orbit 60 is aligned with new applications such as Torsional Vibration and Combustion Monitoring. Orbit 60 has the highest channel density of any system in the marketplace, with up to 80 dynamic vibration and 100 static inputs (such as temperature) and DCS integration into a single system deployment. Versatile I/O options allows for an economic and simple interface to a wide variety of sensors and applications, thus simplifying spare parts inventory. Orbit 60 does not only delivery on features, but value, reducing the overall cost to deploy and maintain protection and condition monitoring systems now and into the future.

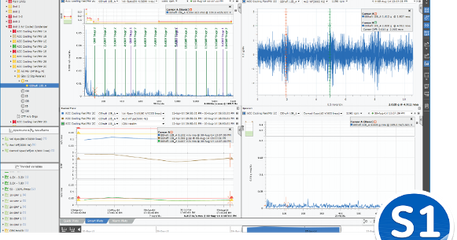

Innovative and secure condition monitoring data connection through the condition monitoring module (CMM) combined with features like advanced signal processing, in-system data sampling, and on device storage of data allow for flexible deployments to truly unlock the power and flexibility of the Bently Nevada monitoring solution.

Traditional deployments of System 1 and Orbit 60 using various network topologies will still be supported but the system will also allow other installations including hosted System 1 installations with no on site IT infrastructure, installations with intermittent or low quality data connections, remote connectivity using cellular or WAN data connections, and cost effective single machine monitoring.

Bently Nevada looks forward to an opportunity to discuss the new platform in detail,please reach out to myself密苏里州或您的销售经理re information.

Product Video - Orbit 60 Teaser

Product Video – Orbit 60 Full length

Orbit 60 Series and System 1: Bloomberg TV