Nexus Controlshas a proven history of delivering dependable, cost-effective distributed control systems (DCS) across a broad range of industries. Our control systemsimprove the reliability and productivity of your operationswith advanced analytics. In industries where safety-rated systems are required, Nexus Controls also offersSIL-certified optionsto meet your needs.

Nexus Controls’ distributed control system is designed to be the ideal central hub for your daily operations. We offer multiple communication links to facilitate easy integration with your existing equipment. Our distributed control system is alsoscalable from low device count applications up to fully integrated plant-wide systems with more than 25,000 devices.

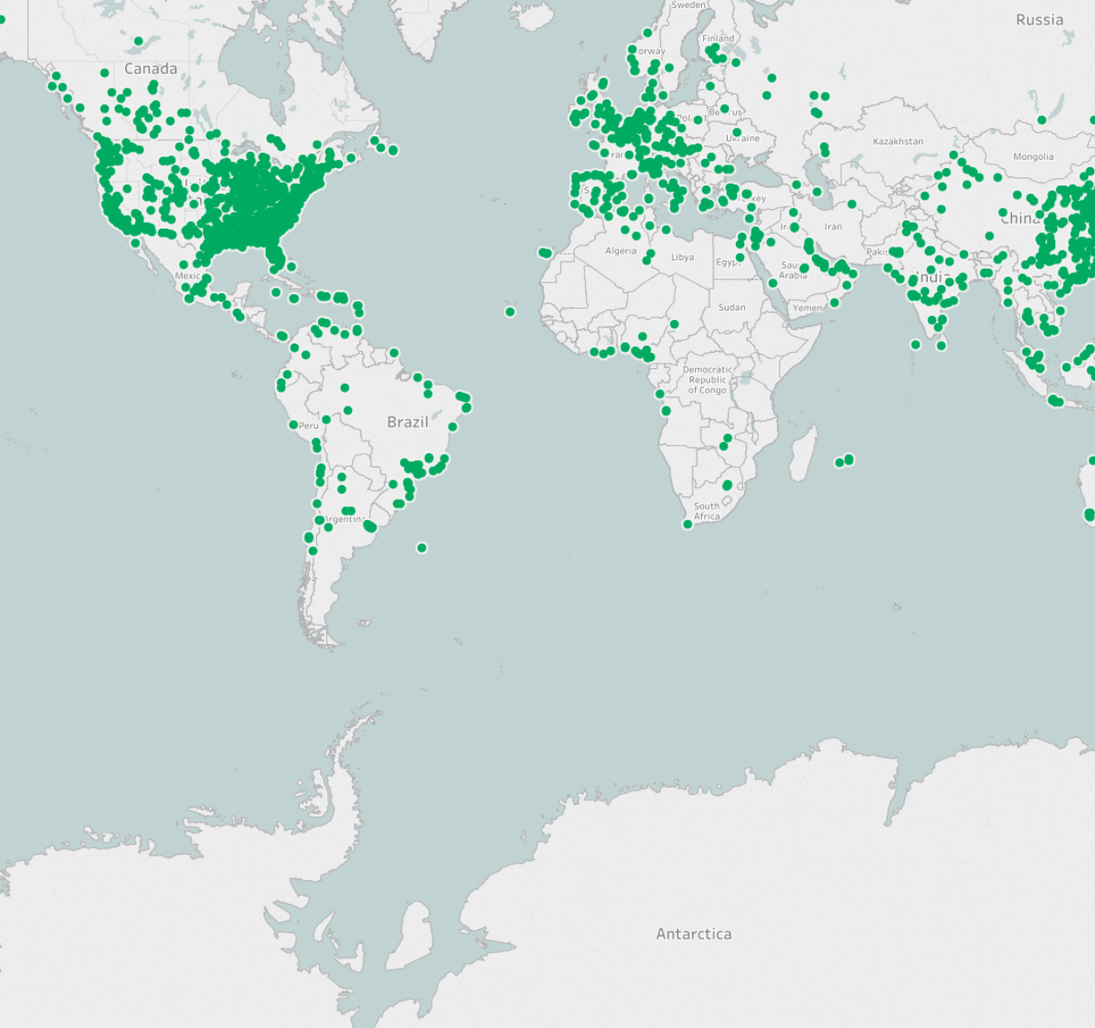

Nexus Controls’ global team of domain experts hassuccessfully completed over 11,000 greenfield and brownfield projects around the world, including extensive Distributed Control System applications across a wide range of industries.

The Nexus Controls global engineering and manufacturing network provides customers withdependable local supportto ensure that your Distributed Control System starts up the first time while meeting your schedule.

Our Nexus OnCore† distributed control system (DCS) has proven invaluable for use in the following industries:

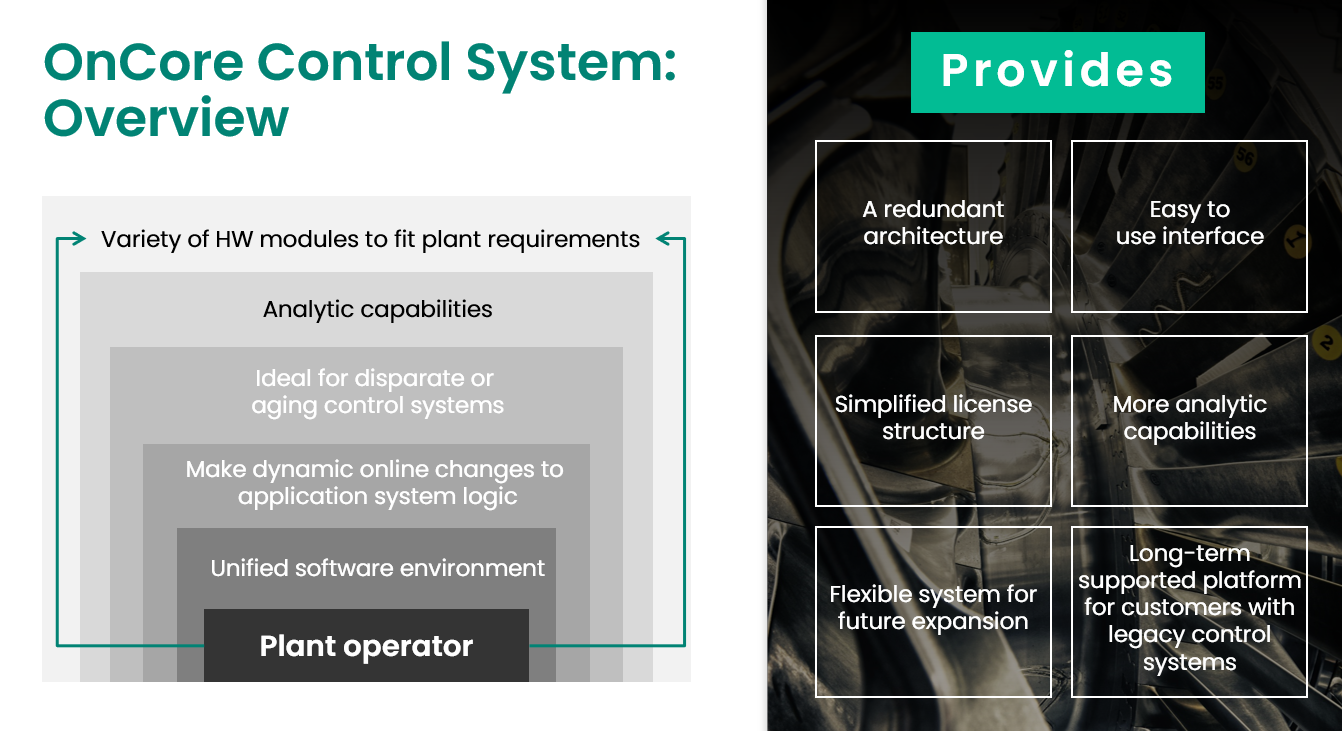

When a plant fails to operate correctly, NexusOnCore†Control System is there to help plant operators improve their decision-making speed and accuracy.

Theunified software environmentquickly and accurately changes the application system logic that controls plant operations in real-time, online.

This capability found with NexusOnCoreControl System optimizes up-time without the need to rely on the manufacturer.

NexusOnCoresystems increase equipment availability, reliability, and maintainability for rotating machines by offering a portfolio that includes critical cybersecurity features and a diagnostic approach to the OEM system vendor.

The NexusOnCoreSafety System is an electronic safety-related system defined byIEC 61508 (2010), with a system capability ofSC 3and a safety integration level ofSIL 3by 2oo3 architectural design.

It can be applied to those applications which require no higher thanSIL 3under low-demand operation mode.

Distributed Control Systemsare powerful tools to help operators improve visibility to their assets, increase response speed and accuracy when the plant fails to operate under normal conditions, andgreater transparency to operations with advanced analytical capabilities. At Nexus, we’ve been working with a range of control systems technologies for decades, helping customers with installation, upgrades, and services.

Through this work, we recognized our customers were facing consistent pain points with their systems:complex licenses packed with additional fees, unnecessarily complicated user interfaces making learning the system onerous, costly system shutdowns for module replacements, among others. This led us to develop theNexus OnCore† Control System.

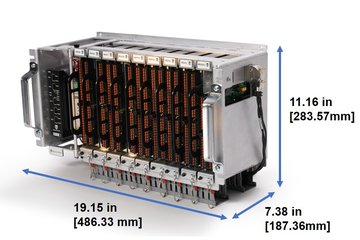

The Nexus OnCore† Control Systemis anadvanced, fully configurable solutionthat improves asset visibility, provides built-in troubleshooting and maintenance tools, offers simplified expansion capabilities, and reduces overall installation and training costs.

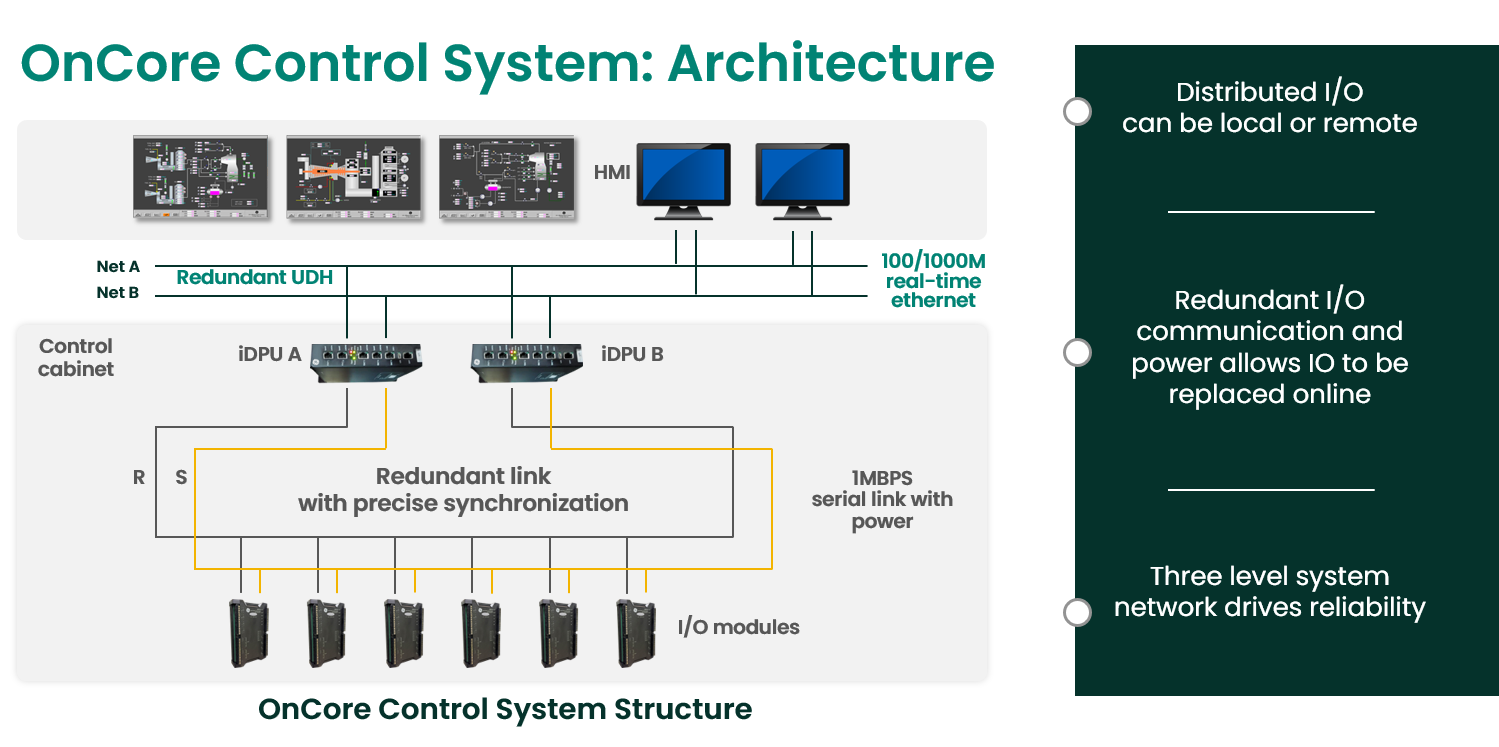

Our redundant I/O communication and powerenable independent module replacement without a total system shutdown. Additionally, a three-level system network provides real-time performance with high-speed data exchange where you need it most – between the controller and HMI. [potentially add more here?]

The Nexus OnCore Control Systemhelps plant operators improve their speed and accuracy in making critical decisionswhen the plant fails to operate under normal conditions

Nexus OnCore HMI software (OptimumC) offers aunified software environmentwith the ability to quickly and precisely make online changes to the application system logic that controls the plant’s operations. This capabilityoptimizes the amount of time necessaryto correct the situation without having to rely on the manufacturer.This gives you the flexibility to manage your operations on your schedule.

Ourintegrated HMI software packageincludes anembedded historianthat can be expanded without additional equipment, saving cost and allowing for more analytical capability.

Easily configured software allows forcustomization of HMI screens, reducing training time while improving the user experience.

A simplified, single licensethat covers all aspects of your process control and safety system means no additional license fees are required in the future if you choose to add points, cards, or expand the capability of the integrated data historian. This flexibility is particularly important as many industries accelerate their digital transformation journey.