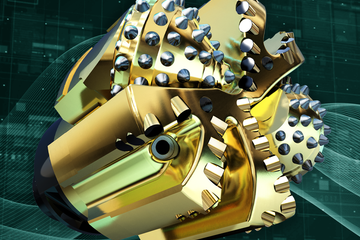

Hybrid drill bit technologyfrom Baker Hughes combines roller cones and polycrystalline diamond compact (PDC) fixed cutters into a single, patented design to reduce drilling time and trips in the most complex applications. With the rock-crushing strength and stability of roller cones and the cutting superiority and continuous shearing action of diamond bits, this technology increases ROP, improves cuttings removal, and survives highly interbedded formations with performance consistency and excellent toolface control.

Higher ROP potential than roller cone drill bits

Compared to roller cone bits, hybrid drill bits can increase ROP, requiring less weight on the bit and minimizing bit bounce.

Optimized drilling dynamics compared with PDC

Compared with PDCs, hybrid bits are significantly more durable when drilling through interbedded formations. They reduce stick-slip and simplify drilling torque management while making it more consistent, enabling smoother transitions through varied formations. Better stability and directional control enable reliable vertical control as well as higher build-up rates in curve sections.

Baker Hughes continues to develop hybrid drill bit technology to widen the application range and deliver high performance in challenging applications for conventional bit technology. Baker Hughes hybrid drill bits are a proven replacement for conventional drill bit approaches, delivering faster and more durable drill bit performance.