Featured Video

Section milling is a conventional methodfor casing removal during plug and abandonment (P&A) operationswhere annular well integrity iscompromised or questioned. The removalof casing by milling a window provides fullaccess to the virgin formation, enablingplacement of a rock-to-rock barrier.Swarf is an unavoidable byproduct ofsection milling,generatingthousands of pounds of sharp metalcuttings that have to be removed from thewell.Retrieving and handlingthe swarfis a time-consumingand costly processand poses additionalhealth,safety, and environmental (HSE) risks, and often timesoperators will optfor less reliable options, like perf-and-wash,just to avoid swarf.

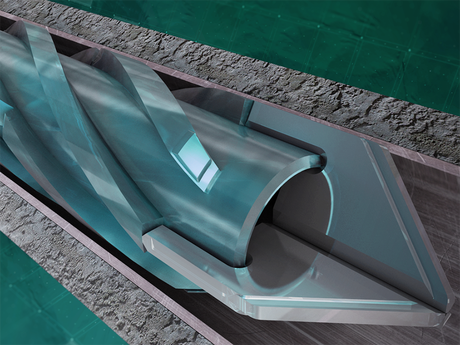

We offer theHEAVY METAL™ swarf-free section milling serviceto provide a reliable solution without the negative side effects of swarf. It eliminates swarf to surface through a unique upwards milling process, depositing swarf deep in the rathole, while still enabling asecurerock-to-rock barrier.This unique system reduces time andcosts in half—eliminating the need for swarfremoval and the risks that swarf presentsto people, equipment, and the environment.

A comprehensive solution

A专门的项目管理团队负责syourentire P&A project—fromtheplanning phase through final abandonment—all with a strong focus on safety and efficiency. With a single point of contact,youachieve a simplified, streamlined process that helps reduce time and minimize risk.