Optimized testing of prototypes and small batches

Automotive light metal casting CT inspection

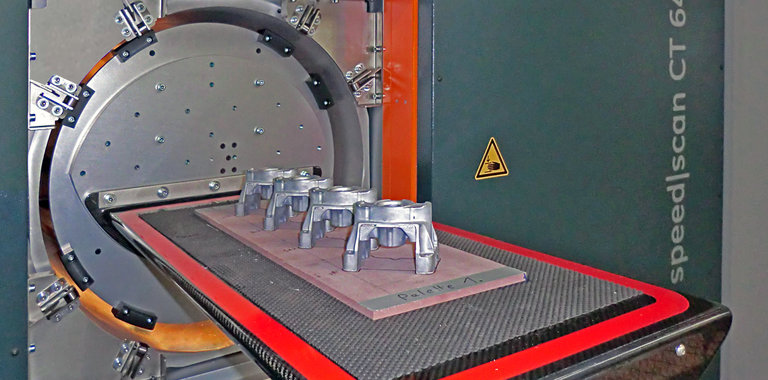

For industrial computed tomography (CT) in foundries, mainly systems based on the principle of fan beam or cone beam tomography are offered. Only Waygate Technologies (Ahrensburg) offers with its Speed|scan CT64 scanner a fast tomograph for the inspection of large light metal castings, which is based on the principle of medical helical CT: It is not necessary to fix the part to be tested on a turntable and to rotate it in the X-ray beam, but it is simply placed on a moving out sample stage.

The CT gantry with its X-ray tube and multi-line detector then rotates around it like in a hospital and scans the part within a few seconds. By simply placing any part on the sample stage and starting the associated test program, practically no set-up effort is required. This allows a wide range of different types of components to be tested flexibly and with high throughput. The special advantage of the fast fan beam helixCT is not only the short scan time, but also the high-quality results, which are particularly low in scatter radiation artifacts. This provides the operator with high-contrast 3D results in a very short time, enabling him to reliably assess the component.

Since 2018, such a fast Speed|scan CT64 tomograph from Waygate Technologies is in use at the light metal foundry of the BMW Group at the Landshut plant. The scope of production includes engine components such as cylinder heads or crankcases, but also body structure parts and chassis parts.

除此之外,光金属铸造用the fast tomograph for 100% inspection of so-called "small series", which can mean more than a hundred parts per day in a foundry with up to 5 million castings per year. Classical defects that can be localized in a non-destructive three-dimensional manner, statistically analyzed and sorted out before further processing steps are porosities, bubbles, residual sand, core failure or cold runs that are not completely filled.

Another important field of Speed|scan applications in the plant is the testing of prototypes and assemblies. As part of process development, these are scanned and analyzed.

The third major field of application of the facility is to assist with the analysis and resolution of quality issues. Conspicuous parts are subjected to a quick check in the Speed|scan, so that a clear result is obtained within less than fifteen minutes.