Designed with professional and advanced visual inspectors in mind, the Everest Mentor Visual iQ is built to meet the highest standards in image quality and 3D measurement capability. Interchangeable probes, platform configurations, and on-device AI deliver productivity while increasing probability of detection and inspection accuracy.

OS 3.7 software is now available for the Everest Mentor Visual iQ. With this new software, all assisted defect recognition analytics on the MViQ video borescope can function in a live state. Now 3D Stitching is available with Real3D Stereo Measurement, your MViQ can generate a fully-surfaced 3D point cloud representation of the asset that makes it easier to analyze and measure the defect you've spotted. This update also features new tips that expand your envelope of application, allowing you to inspect from closer and farther away than ever before.

- Military grade portable design with bright LCD touchscreen display and integrated connectivity options

- Real3D™ measurement provides advanced tools, including auto-measurement, measurement from/to a projected plane and 3D stitching of multiple images.

- Leveraging computer vision and machine learning, powerful analytics are available to increase reliability and consistency of data collected while reducing inspection time by automating repetitive tasks.

Push2IW automates your data upload process by automatically sending images and data from your MViQ video borescope to the InspectionWorks cloud.

- Streamlines inspection workflows with Menu Directed Inspection (MDI) and InspectionWorks.

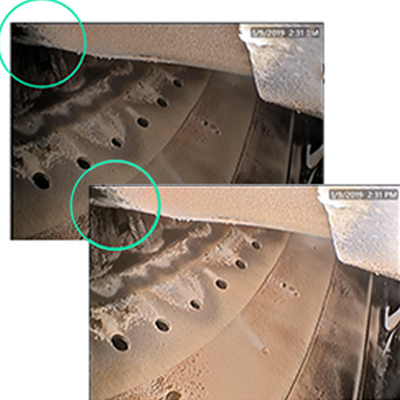

- Optional Probability of Detection software and image transforms leverage TrueSight™ to ensure you don’t miss an indication.

Mentor Visual iQ

Industry-leading1.2-megapixel HD image resolutionboasts high-quality images and videos for your inspections. When you can see clearly, you increase the probability of detection, speed up inspection workflow, anddeliver results with confidence.

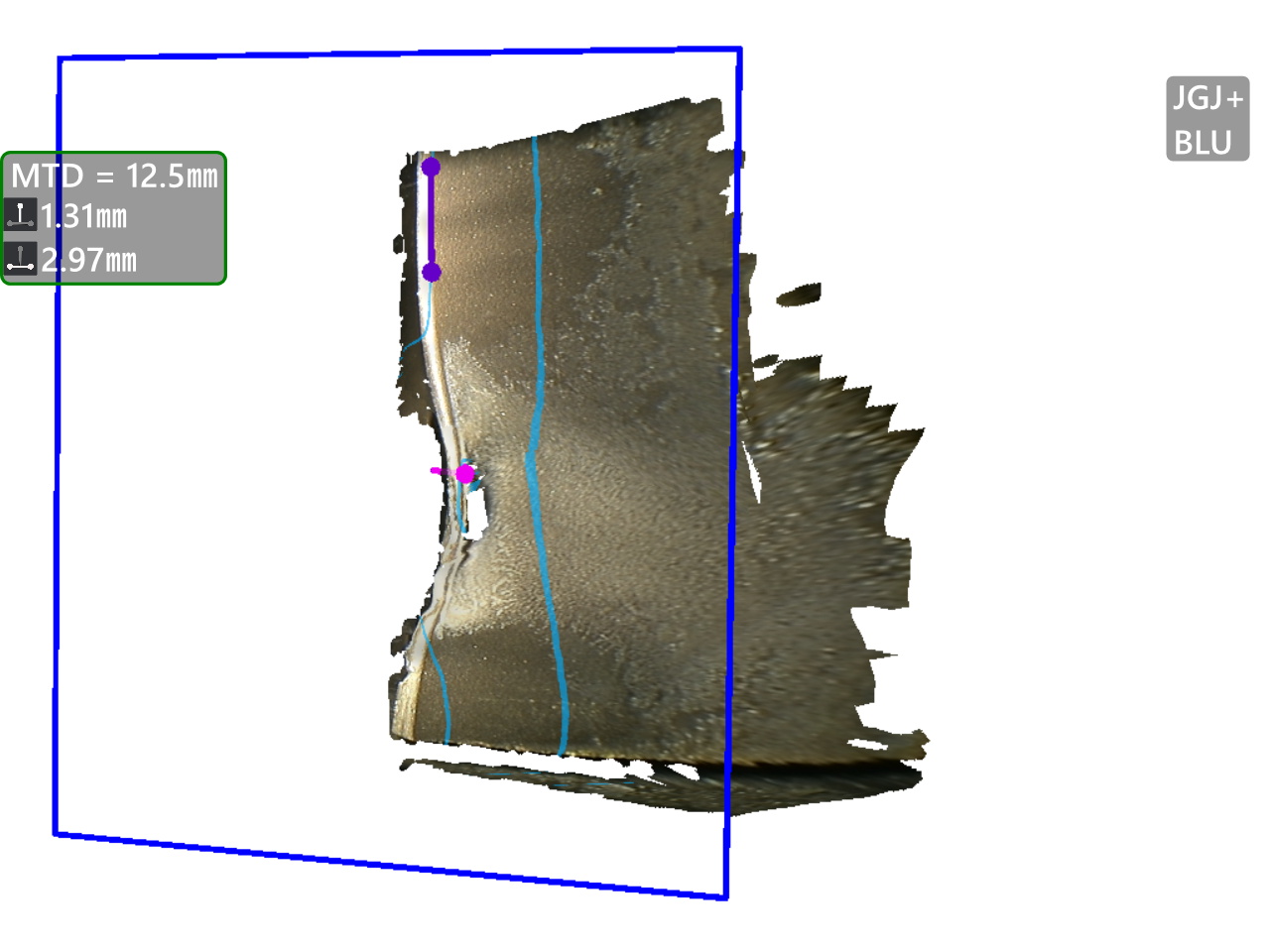

Inspect, interrogate and report more of the scene with3D Stitching. Combining individual images, and corresponding point clouds, to a larger image enablesmeasurement of larger defectsacross multiple images and the ability toaccurately locate the positionof defects in relation to a fixed point-of-interest.

TrueSight™ provides a blend ofhigh resolution image capturing and processing functions,precision opticsand a powerful suite ofproprietary image transformsused to enable better visual inspection decisions.

The suite of image transforms is included in the Analyze model and available on Touch and Inspect models when ordering our Probability of Detection SW package.

This POD SW includes the following (click to watch videos):Adaptive Noise Reduction (ANR), Dark Boost,Distortion Correction,Inverse+,Variable High Dynamic Range (VHDR)andColor Saturation.

Real3D™ measurement combinesfully surfaced point cloud visualization, advanced measurement algorithms and aninsightful 3D Surface Maskand adynamic warning systemto enable more accurate and repeatable measurement decisions.Choose from three measurement technologies(3D Phase, 3D Stereo and traditional stereo). 3D Phase measurement allows measurement on-demand without changing tips.

这些技术兼容or all of our 9 measurement types to help get the measurement needed in multiple applications. They include basics like length, depth point to line and area, but also specialty types including depth profile, area depth profile, automatic tip blade clearance and radius gauge.

Aside from measurement types, Real3D provides advanced tools such asdepth assistandprojected measurement planeto further increase accuracy of measurements.

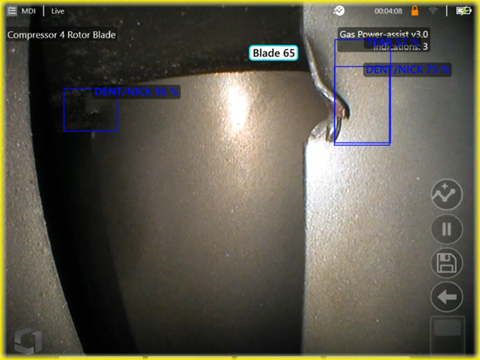

Leverage computer vision and machine learning to help improve consistency and reliability of inspection tasks and increase the overall quality of an inspection output. The Mentor Visual iQ enables users to leverage analytical models from multiple sources.

Waygate Technologies Analytics.Powered by InspectionsWorks Analyze,Gas Power assistandBlade Counterare analytics developed to improve reliability and data integrity

Third Party Partner Analytics.Available directly on the Mentor Visual iQ, users can leverage Aiir Innovations’ aviation commercial engine models for defect detection

Third Party Private Analytics.For customers developing their own analytics, the Mentor Visual iQ enables deployment to a global team

InspectionWorks is a software platform which provides a suite of digital tools used to make inspections consistent and more efficient, while turning inspection data into a tool for faster and better decisions.

- InspectionWorks连接provides collaboration and real-time access to experts.

- InspectionWorks Insight is a comprehensive data management and inspection database enabling global access to data and analytics. With Push2IW, data is automatically pushed to the cloud during the inspection to streamline data management and ensure against lost data.

- InspectionWorks Store, Public and Private, provides access to workflows and reference libraries. The Public stores contains manuals, analytic data sheets, MDI templates, and other reference materials. The Private store is available to share with members of your InspectionWorks account and distribute custom MDI workflows, analytics, reference documents, or any other resources your team may need.

Constructed with military-grade durability (MIL-STD) to withstand the rigors of the industrial workplace, you can trust your Mentor Visual iQ videoscope device to deliver top performance in even the harshest environmental conditions.

标准的遵从性和分类:

- MIL-STD-810GUnited States Department of Defense Environment Tests Sections 501.5, 502.5, 506.5, 507.5, 509.5, 511.5, 514.6, 516.6, 521.3

- MIL-STD-461GUnited States Department of Defense - Electromagnetic Compatibility with RE102 and RS103 - ABOVE DECK

- Standards compliance Group 1 Class A; EN61326-1, IEC CB Scheme, UL/EN/CASE-C22.2 61010-1, IEC 62133, UN/DOT T1-T8, EU RoHS 2, EU RED Drective, ISTA 2G, UKCA

- IP rating: IP65 (assembled), IP55 (disassembled)

Benefits

- Adapts to all Waygate Technologies rigid borescopes and fiberscopes

- Can also adapt to rigid borescopes and fiberscopes from other manufacturers

The Mentor Visual iQ delivers the latest advancements in measurement technologies and advanced analytics by providing easy wireless upgrades and planned software releases so you can keep equipment up to date and stay ahead of the curve. You can try out all our new features with the 90-day free trial that comes with your MViQ. Visit InspectionWorks for details and additional resources.

Contact us to schedule your own on-site or virtual demo to understand the full capabilities of the Mentor Visual iQ and how it can increase your POD.

Our support team offers consultations to help you figure out which Borescope will be best fit for your inspection device needs.Contact one of our experts.

With the power of Real3D™, the MViQ can measure length, area, depth, multi-segment, depth profile, measurement plane and area depth profile.

The Mentor Visual iQ has 1.2 megapixel HD sensors to increase image quality up to 1.7 times clearer than standard models operating at 440K pixels. This allows you to zoom into indications until they're nearly 70 percent larger, ensuring the most accurate analysis possible.

We work to get you your rental equipment fast, so you can lower your downtime. Learn more about our rental programshere.

A free 90-day trial should be activated after installing your 3.7 software. After that, contact your local Waygate Technologies sales representative.

Yes. Waygate Technologies is committed to delivering Inspection Solutions to the inspection industry. Please contact your local Waygate Technologies sales representative to discuss your needs.

由于燃气轮机architectu的共同本质re and defect classifications, it is likely that this ADR analytic remains application to other gas turbine types beyond those listed in section 4.0.

Note that LMS100, LM2500, AND LM6000 are aeroderivative of the CF6 aero gas turbine series.

ADR improves consistency and reliability of inspection tasks by leveraging Computer Vision technology to assist the trained Inspector in conducting the visual inspection. It also reduced the probability of missing indications on critical turbomachinery components. ADR also provides automatic annotation for the user to approve, and it increases the overall quality of inspection output.

No. The analytics operate entirely standalone within the device.

Yes. The ADR can process on recalled images within the MViQ "Flame" handset. Such images can be: those that have either been previously processed using this analytic; or raw/unprocessed images. Inferences can be generated and subsequently saved for presentation or inclusion into the inspection report.