Phoenix Speed|scan HD

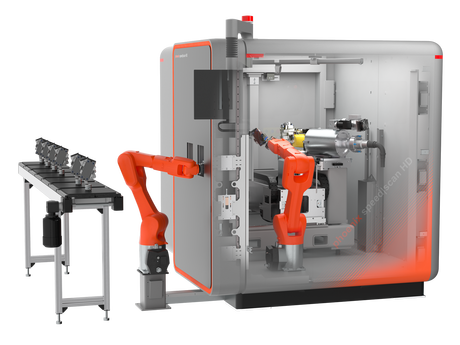

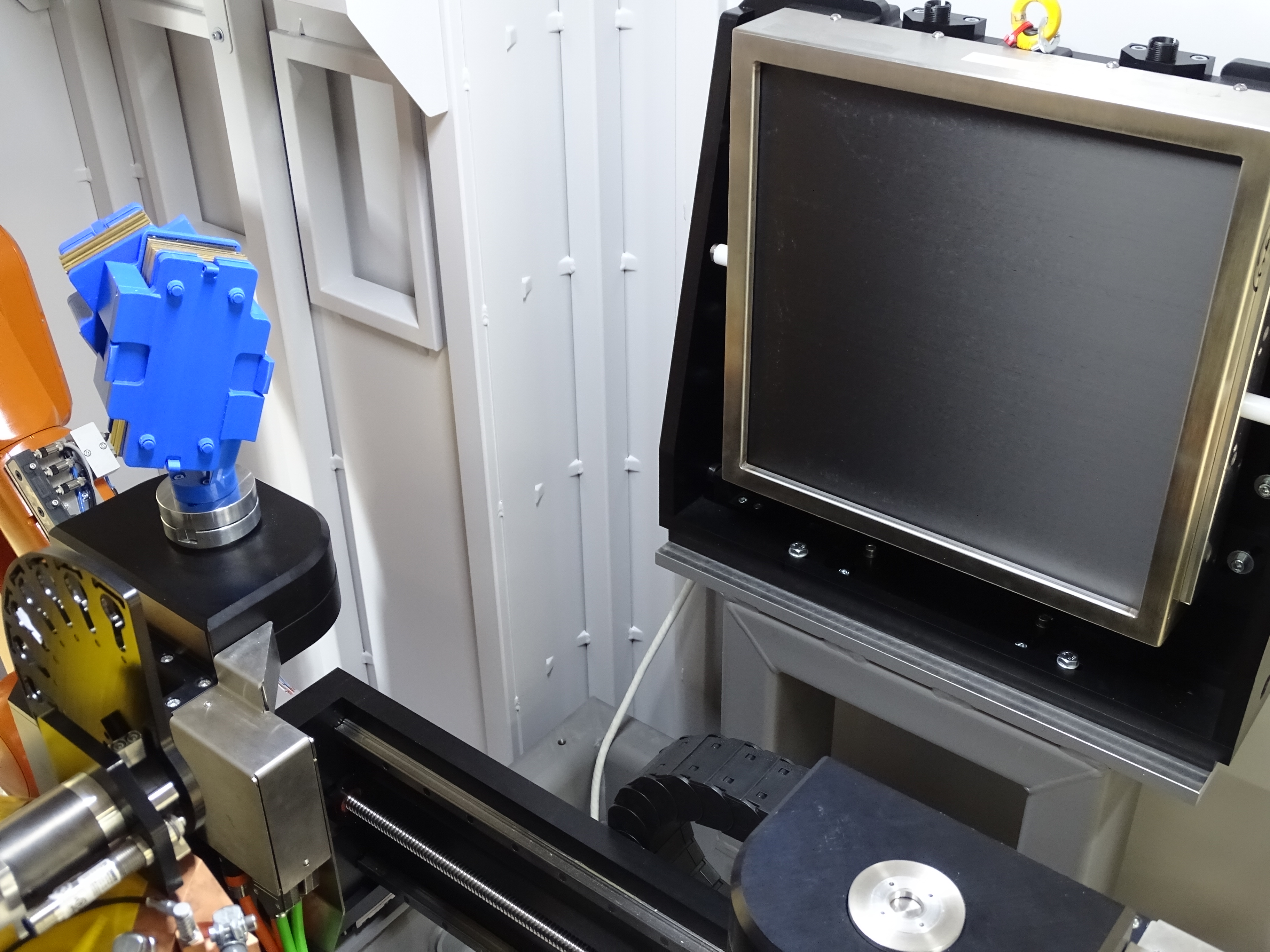

Complex production lines e.g. in battery manufacturing, must safely and consistently turn out high-quality parts and products. Waygate Technologies offers the Speed|scan HD - a fully automated high speed inline Computed Topography (CT) system for production process control and optimization. Based on more than 20 years of industry proven technology, the Speed|scan HD system supports microCT inspections for up to 100% of production volume, helping you to reach your zero defect target.

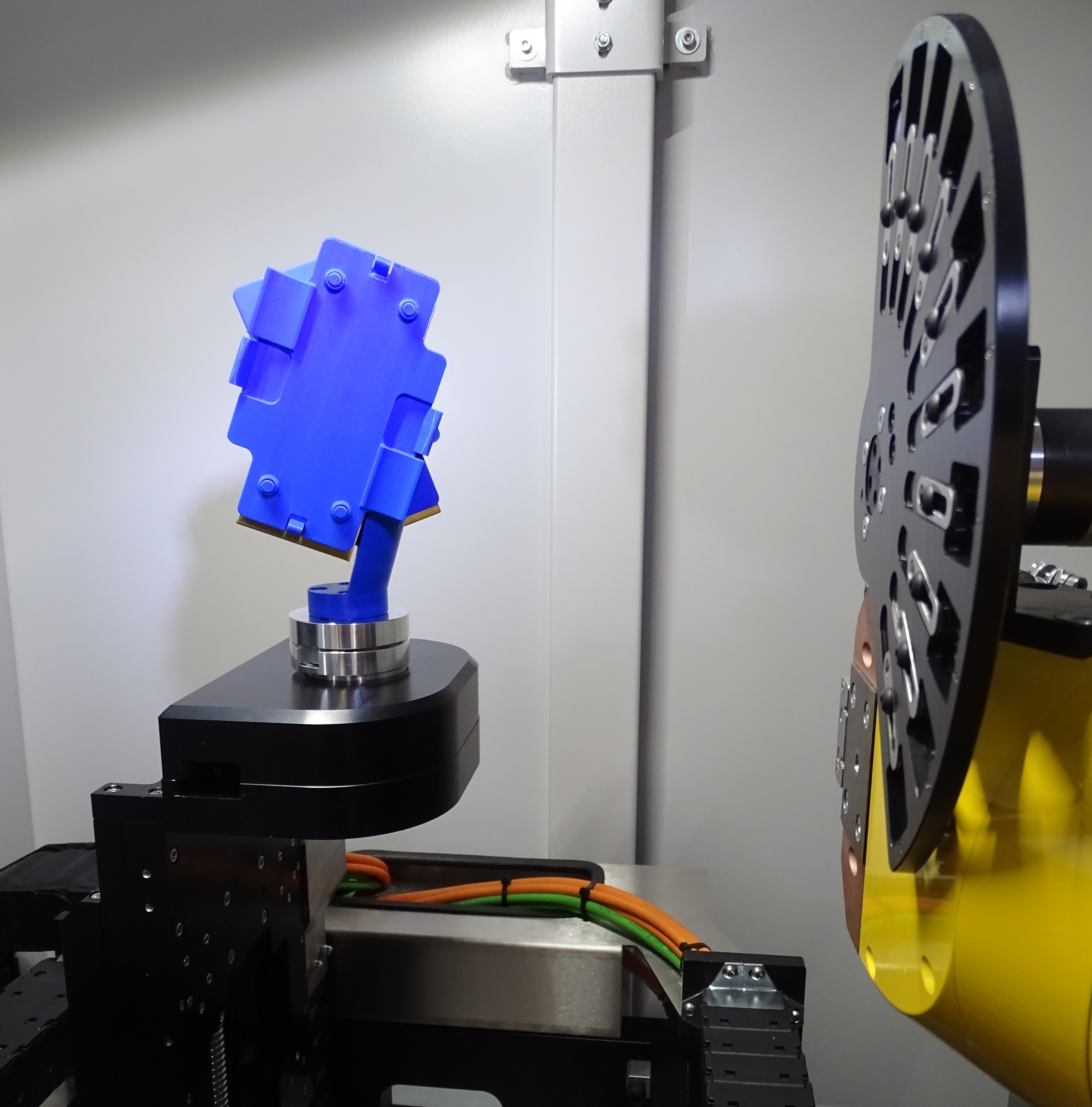

The Speed|scan HD system is designed to allow full 3D production control across a variety of applications, including electronic devices, batteries, connectors, injection moldings, complex assemblies and AM parts.

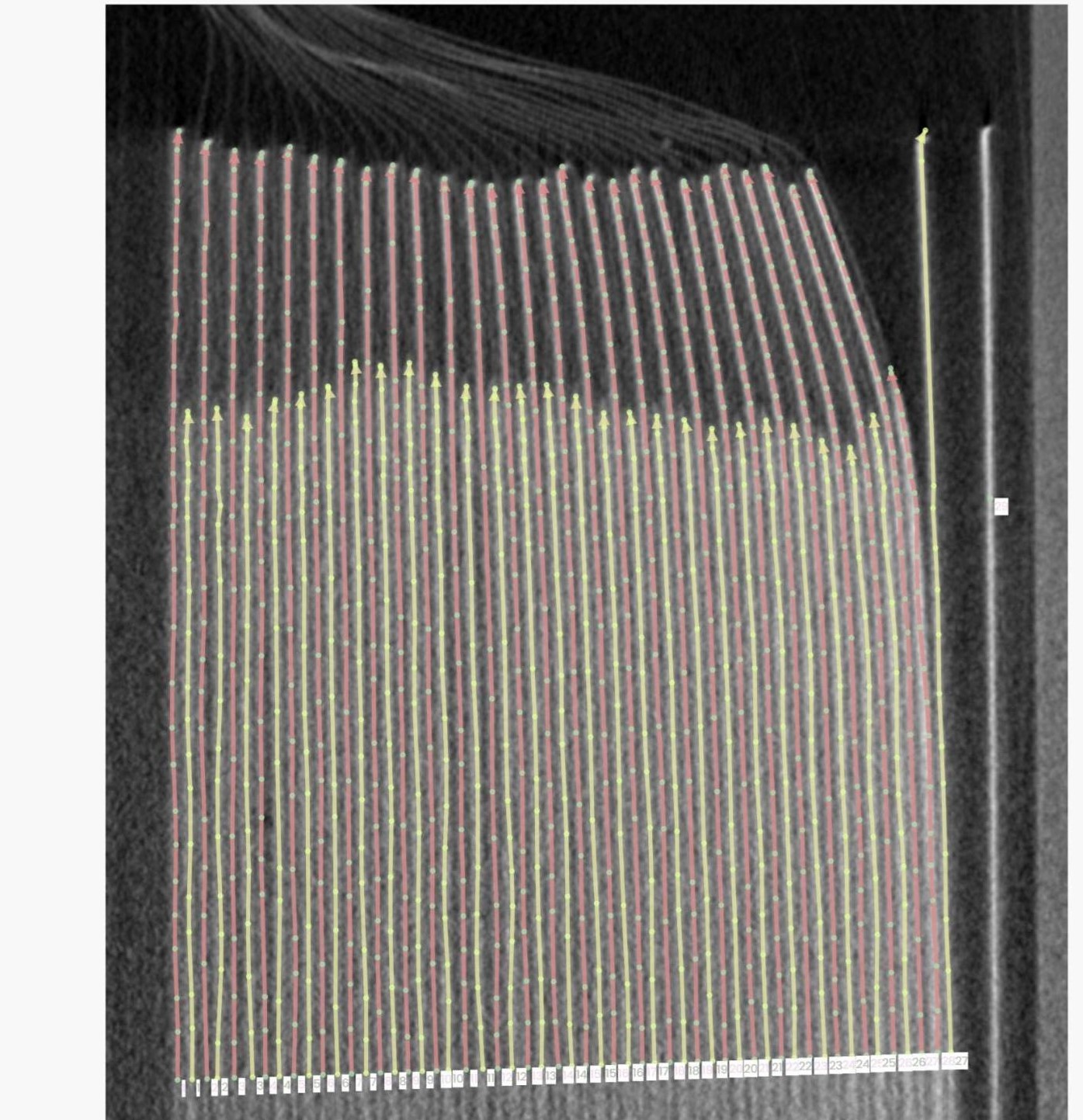

Fully automated parts handling and a bundle of CT innovations enable 24/7 Speed|scan HD operation at exceptional voxel resolutions down to 25 microns - with the optional Dynamic 41|100 detector even 12.5 µm. With advanced artificial intelligence (AI) - based-battery anode overhang analysis as well as automatic defect recognition (ADR) for pass/fail decisions and fully automated CT workflows, the Speed|scan HD system is setting new standards for reliable and precise production control.

Highlights

Unique Benefits

- Reduced number of rejects and recalls - both internally and externally

- Lower cost of quality

- Faster product ramp up and production process optimization

- Scanning time <1 minute possible

- Infinite part mix - Each individual part of a test series can be tested automatically with other parameters and filters, without manual setting

- Significantly less user interaction than conventional CT technology

- 90% to 98% reduction in operator time due to robotics, automated workflows and AI based automated defect recognition (ADR)

- Typical throughput 30% higher vs. traditional CT scanners

- 5 to 10 times greater throughput compared to manual inspection

Features

- High-speed and high-volume inspection capability as a result of advanced microfocus and detector technology

- Increased tact time delivered via double X-ray security gates for continuous radiation

- Enhanced throughput achieved through fully automated part handling

- Robust design for 24/7 operation in an industrial environment

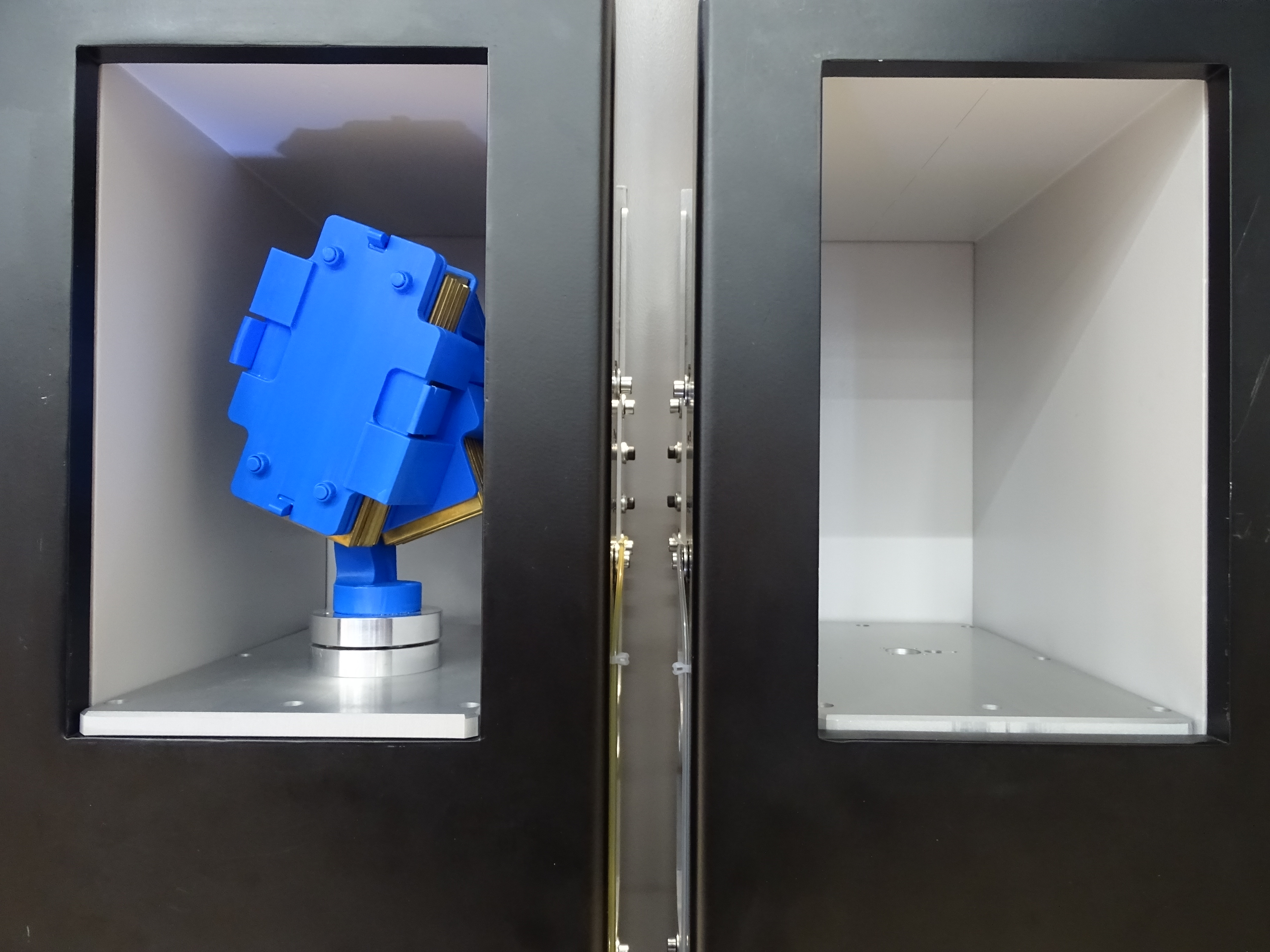

- High part mix flexibility due to automated Filter|changer

- Parallel reconstruction of data sets and evaluation

- Proprietary, rugged microfocus X-ray tube (Inline|edition, 240 kV/100W) designed for production environment

- Proprietary Dynamic 41|100 or Dynamic 41|200p+ X-ray detector for long-term stability and best resolution

- Two-stage manipulation system for increased cycle times

- Artificial Intelligence optimized automated defect recognition (ADR) for evaluation without human interaction

- Remote monitoring and diagnostics with InspectionWorks Care for increased system availability

Proprietary, open, directional,high-power 240 kV/100 W microfocus X-ray tubespecifically designed to deliver exceptional reliability and reproducibility on the manufacturing floor in 24/7 operation (Inline|edition).

- Dense material penetration

- Detail detectability down to 20 μm

- Liquid cooled for high reliability

- "Unlimited" lifetime due to open tube design: All major components like filament and target can be exchanged by the operator

Part mix scanning just got easier. With Filter|changer - which canhost up to 10 different hardware filters-you can redefine filter parameters for specified inspection tasks so that the filter settings areautomatically adjusted before scanning.

- Increased flexibility when running part mix

- Fully automated workflow without user interaction

Specifically developed for longterm stability and reliability at industrial highenergy use in production, ournext-generation flat panelX-ray detector platformdelivers up to 10 times more efficiency and sensitivity than conventional technology 200 μm pixel DXR detectors. Lifetime has considerably been increased to meet the demands of inline applications.

- High efficiency and sensitivity for short inspection cycles

- High signal-to-noise ratio (SNR) for excellent image quality in production environment

- 25 µm voxel resolution with Dynamic 41|200 or 12.5 µm with optional Dynamic 41|100

- Dedicated to industrial high energy and inline applications

- Exclusive available only for Waygate Technologies customers

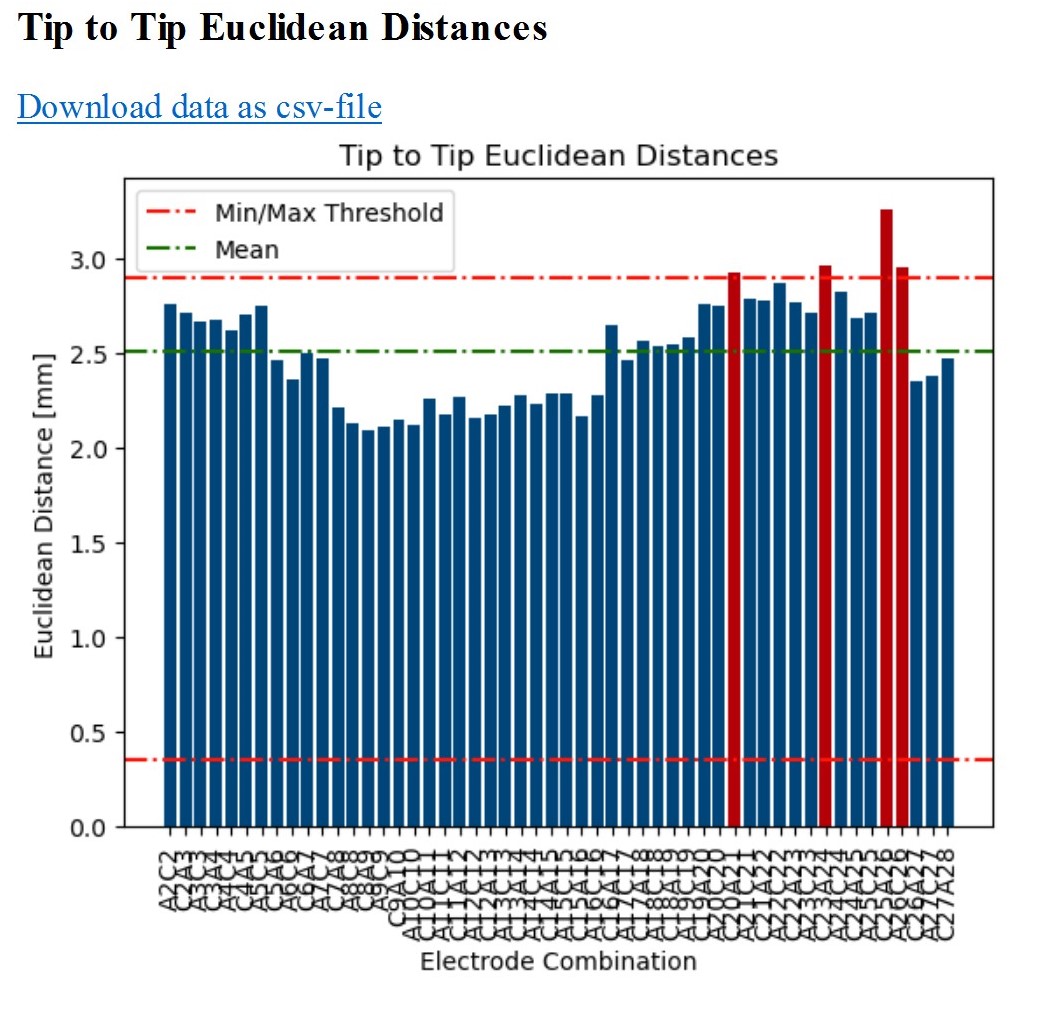

Proprietary Artificial Intelligence (AI) based algorithms deliverexceptional Automated Defect Recognition (ADR)across various flaws for e.g. battery anode overhang analysis or typical casting defects. Our AI-based ADR library yields greater accuracy and enhanced ease of use compared to conventional ADR approaches,eliminating the need for expert parameterization skills.

Waygate Technologies offers theX|approver, the next level and premium ADR platformconsisting of the full and intuitive workflow management as well as a comprehensive ADR library running in the background of your production delivering automatic decision making. On top of it reporting functions are provided to see potential negative trends in production at a glance.

Any authorized operator can parametrize scanned samples (e.g. for highly accurate overhang issue detection), and the algorithms get more accurate over time.

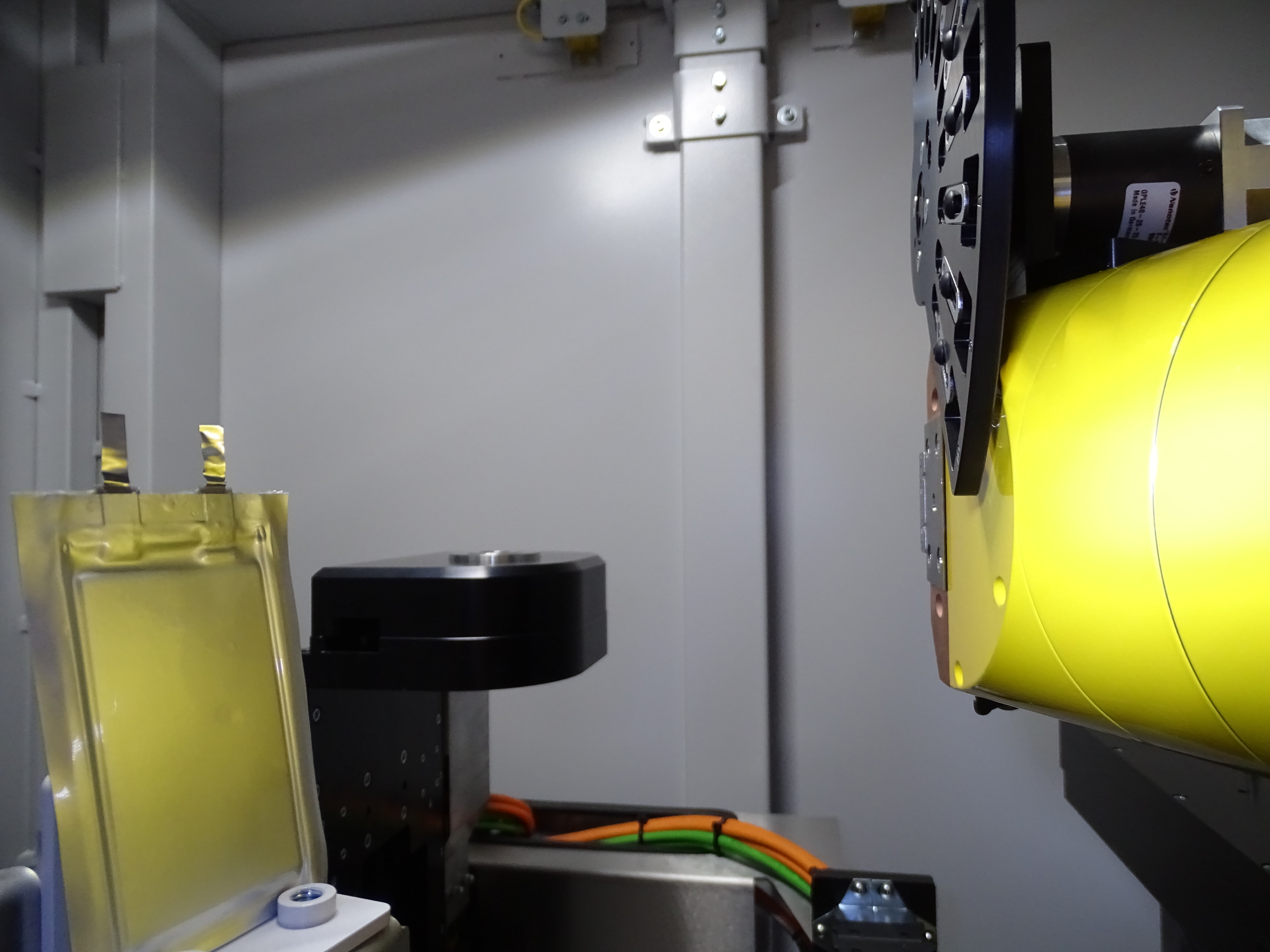

Unique manipulation system uses两个操作单元缩短检验周期s. While one unit is active in the X-ray beam, the other manipulator is loaded and ready.

- Reduced loading/unloading wait times

- Shortened tact times

Two security gates allow forcontinuous X-ray even while loading and unloading. Two robots (inside/outside) provide smooth and fast part handling capability.

- Smart loading/unloading gates for enhanced productivity

- Robot supported, fully automated workflows eliminate need for human interaction

The equipment health data of your core components can bepushed via our RM&D system InspectionWorks Care to our remote experts快速诊断和preventiv系统e maintenance to reduce potential downtime risks.

- Expert issue resolution

- Maximized uptime

- Increased system availability

Technical specifications and configurations

Phoenix Datos|x 3Dcomputed tomography acquisition and reconstruction software as well asPhoenix Datos|approverfor AI based battery anode overhang analysis.Optional 3D evaluation software packagesare available upon request for 3D metrology, failure analysis, and structural analysis.

The Speed|scan HD employs a radiation safety cabinet for full protective installation without type approval according toGerman StrSchV/StrSchGand in compliance withFrench NFC 74 100andUS Performance Standard 21 CFR Subchapter J. For operation, other official licenses may be necessary.

The Speed|scan HD uses atemperature-stabilized Dynamic 41|200p+ large area detectorwith superior image and result quality, 410 x 410 mm (16” x 16”), 200 μm pixel size, 2036 x 2036 pixels (4 MP), extremely high dynamic range > 10000:1.

The maximum part weight is2 - 4 kilograms, depending on the application.