With more than 40 years of experience in automated industrial inspection of aerospace parts and a large installed base all around the globe, Waygate Technologies is a trusted partner in aerospace material testing. Many customers operate multiple machines, having placed their trust in RokStar for decades. The system is well established in the market because of its proven productivity and performance. Our experts work closely with our customers to tackle any challenge – from choosing the best overall inspection line set-up to customized solutions for specific inspection tasks. If desired application feasibility studies can be performed in our application lab.

Next level composite inspection performance

- Market leading accuracy

- 出色的可靠性

- Highest productivity

- High versatility

- 40+ years experience

- 50+ installations worldwide

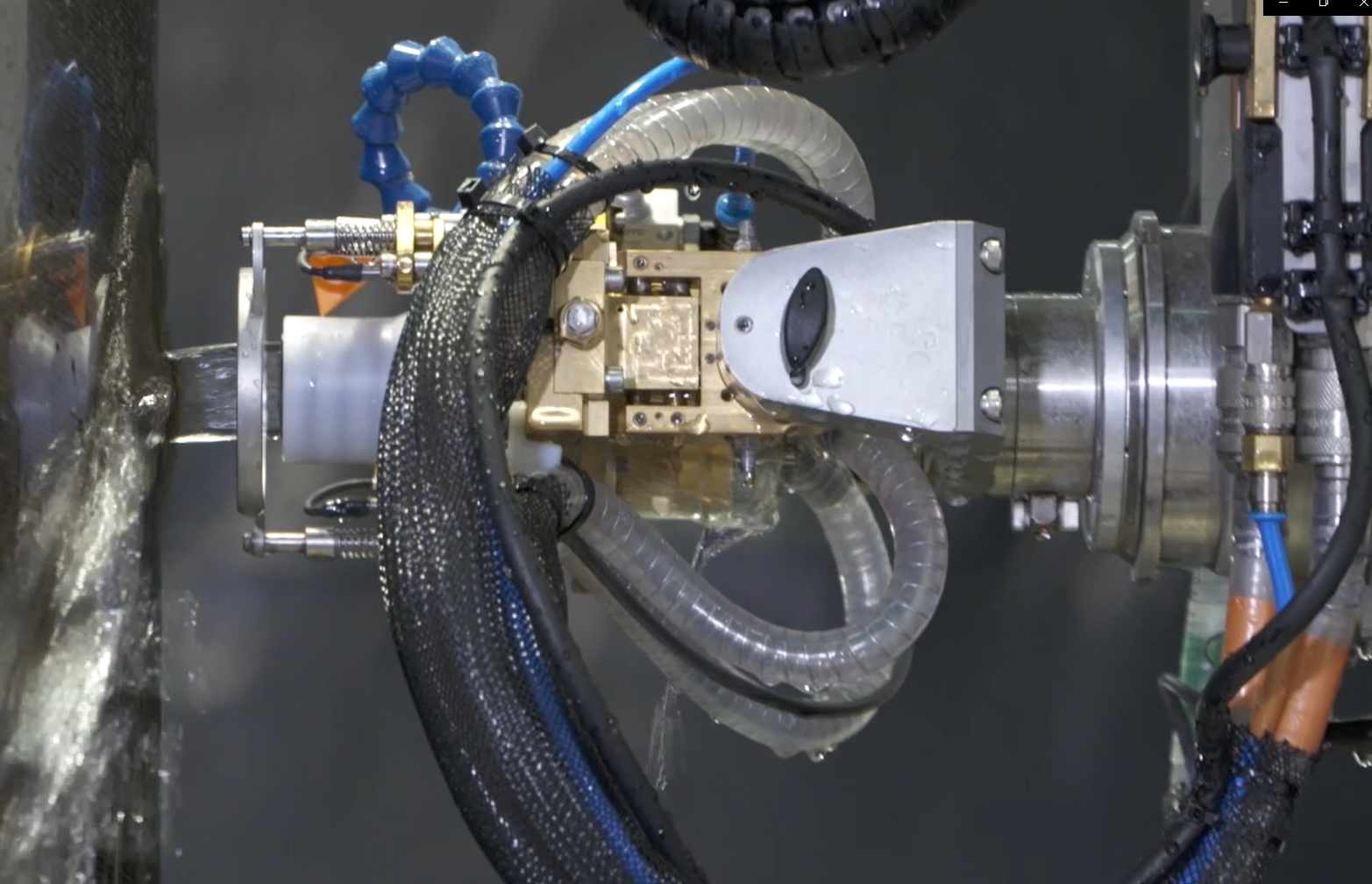

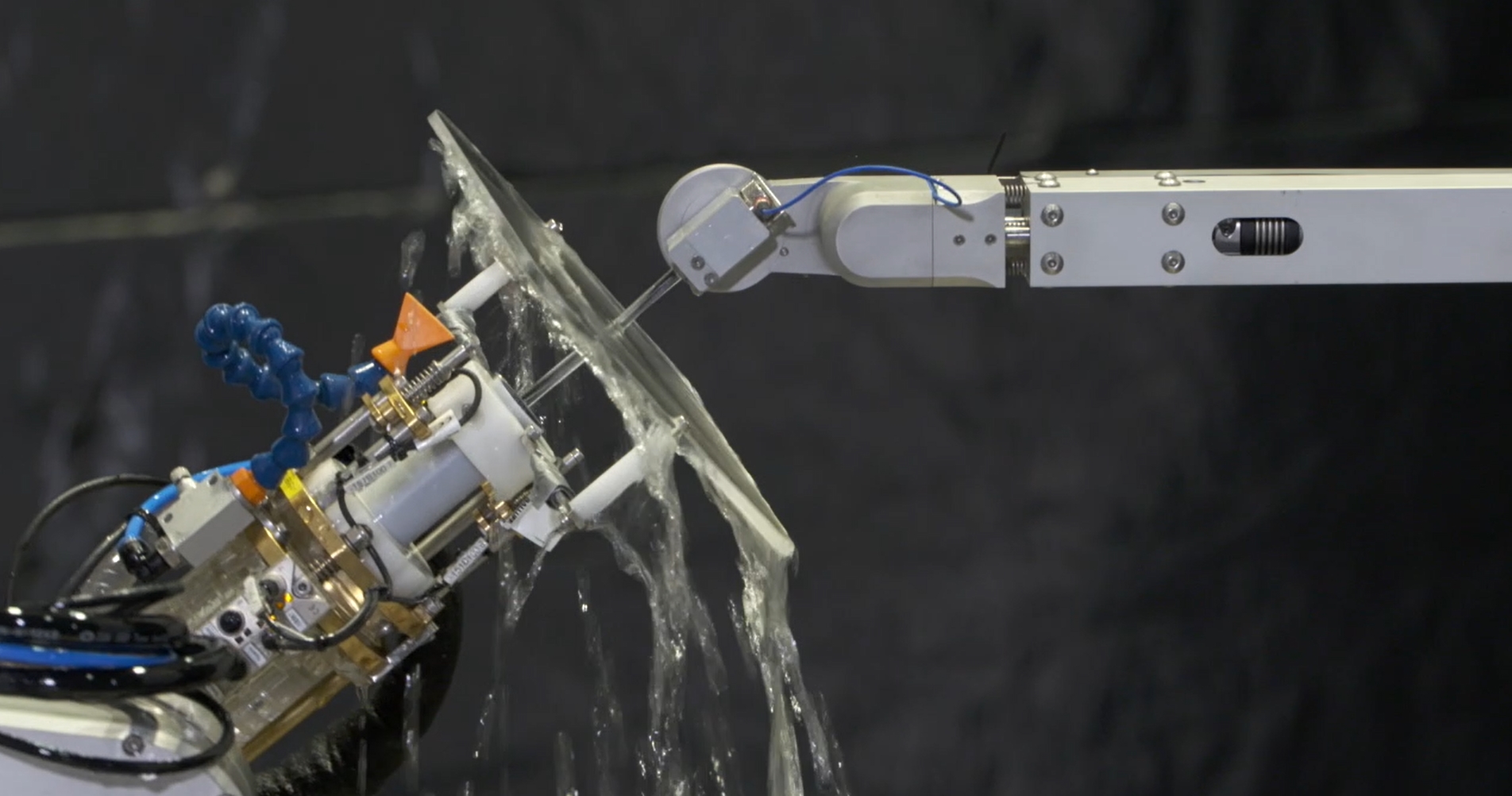

Krautkrämer RokStar is a hybrid ultrasonic testing machine combining the dimensional control of cartesian gantry systems with the flexibility of articulating robot solutions. The result is a solid 13-axis scanning system with a broad field of application and universal scanning possibility. Using a wide selection of tool sets, it can accurately and efficiently inspect a large variety of manufactured parts: from large, relatively flat wing skins to small, complex 3D components on defect types like delaminations, inclusions, debondings, voids, porosity etc.

The robust test mechanics are considered the most accurate test mechanics in the market using low tolerance components made of stainless steel to ensure maximum precision, even for the inspection of large parts. The water filter system uses many different filter techniques for all relevant impurities. It thereby guarantees high-quality coupling water for every test application and facilitates the best results.

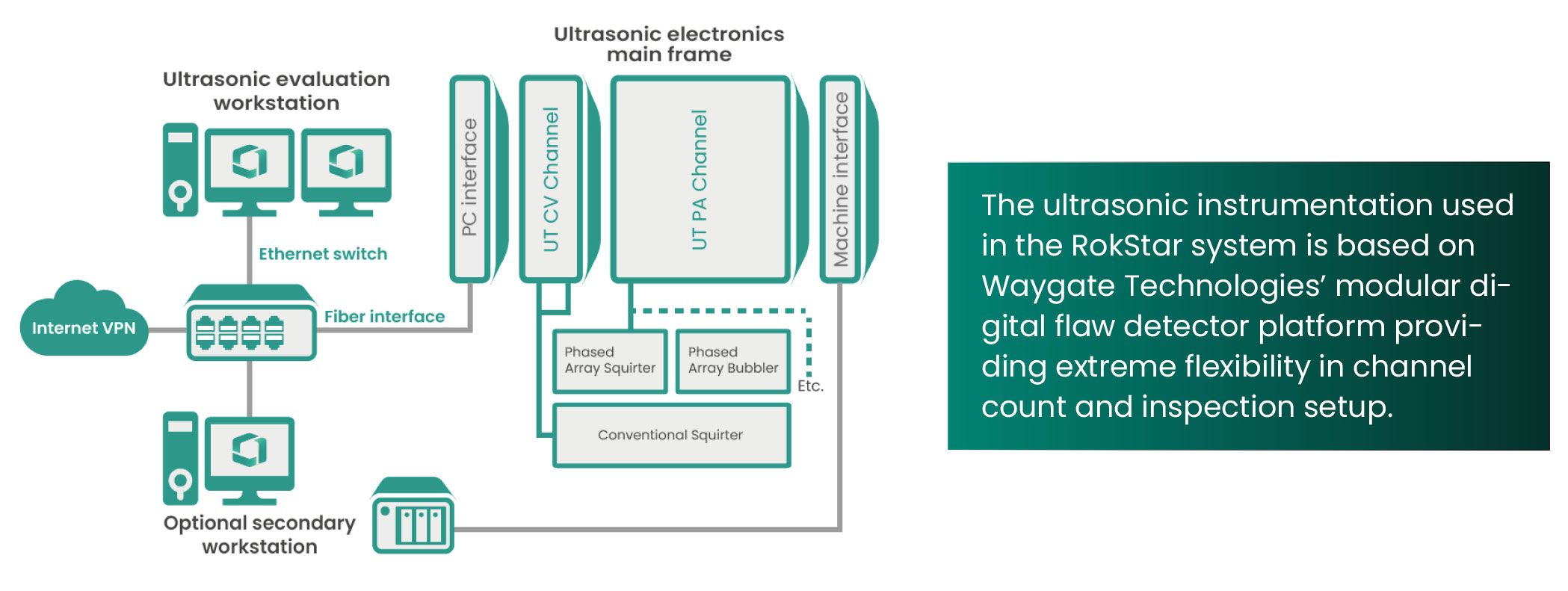

A multitude of modular UT electronics is available, ranging from high-precision single-channel applications to external high-performance transmitters as well as multi-channel phased array packages for critical application needs and highest test speed requirements.

脉冲回波,通过传输检查帽abilities are available individually but also in combination to maximize productivity.

With more than 40 years of experience in automated industrial inspection of aerospace parts and a large installed base around the globe, Waygate Technologies is a trusted partner in aerospace material testing. Our experts work closely with our customers to tackle any challenge – from choosing the best overall inspection line set up to customized solutions for specific inspection tasks.

Many customers operate multiple machines, having placed their trust in Rokstar for decades. The system is well established in the market because of its proven productivity and performance.

Krautkrämer RokStar’s unique design guarantees enhanced stability during scanner movement. The scanner rides on two steel beams in the primary X direction. All other axes are interpolating indexed axes. For scans of complex 3D parts, the machine uses an additional trigger axis to ensure equidistant data acquisition through the entire scan path. Individual testing mechanics designs and options like turntable, defect markers, customized tool sets etc. are availably to accommodate different part inspection requirements.

- High performance mechanics “Made in Germany”

- Geometry teach-in from CAD models, laser metrology and manual methods

- Patented Reverse Phasing Contour Adaptation (RPCA)

- ALOK data compression

- 1 software to cover scan plan set-up & data evaluation

- Data analysis to main aerospace manufacturing standards

- Digital interfaces to Manufacturing Execution System (MES)

- 主要航空航天制造标准兼容s

- UT instruments compliant to all relevant NDT standards

- On site UT instrument certification with our CERT-2 system

- Local service support incl. global Tech-Support Team

Dual frequency inspection in a single pass using Waygate Technologies annular ultrasonic transducer design, achieving twice the throughput of conventional single channel squirters.

Waygate Technologies patented phased array squirters provide up to a 15 mm wide scan area in a single pass.

Provides Pulse Echo inspection with up to a 86 mm track width in a single pass. Geometrical variations within the test part are compensated by Waygate Technologies patented RPCA (Reverse Phasing Contour Adaptation) method.

Inspects concave (inner) radii in a single scan track/path. Geometrical variations within the test part are compensated by Waygate Technologies patented RPCA (Reverse Phasing Contour Adaptation) method.

Inspects convex (outer) radii in a single scan track/path. Geometrical variations within the test part are compensated by Waygate Technologies patented RPCA (Reverse Phasing Contour Adaptation) method.

Allows access to narrow passages to facilitate TTU inspection with an additional rotational axis at the end of the extender and miniature squirter nozzle.

Provides Pulse Echo inspection of the stringer web of T-shaped stringers or variations of it typically in a single pass at 100% coverage using a phased array probe with up to 128 elements.