Highlights

Highlights

Benefits

- Resist deposition of all manner of scale

- Resist impact damage on pump stages due to solids

Applications

- High sands/solids production environments

- Producing wells prone to significant scale formation

Overview

Get superior scale resistance for your electric submersible pumping (ESP) stages withArmor™ I protective coatingfrom Baker Hughes. Our proprietary fluoropolymer coating resists buildup of asphaltenes and scale while minimizing abrasive wear—ensuring extended run life for your ESP system at minimal expense.

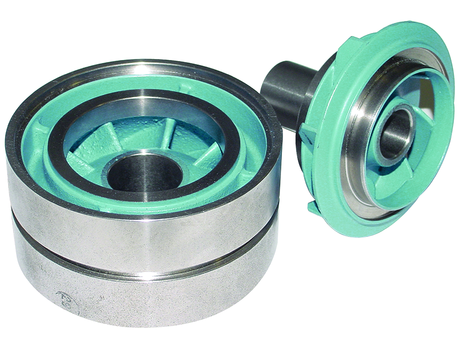

This impact-resistant coating protects critical areas in each pump stage, including impellers, diffusers, the bottom diffuser, and modular thrust bearing components. Armor I is applied to each component through multiple dip baths, which builds the coating to a uniform thickness of up to 0.5 mils (thousandths of an inch).

Once applied, the Armor I coating reduces the risk of pump plugging due to scale, asphaltenes, and moderate abrasives—increasing system uptime while lowering operating costs.

Contact us to learn how Armor I protective coating can optimize the performance of your ESP system.