Highlights

Highlights

Benefits

- Reduced time to first oil

- Lower TOTEX

- Flexible over life of field

Features

- Structured product with effective execution model

- Simpler configuration in smaller size with reduced weight

- Life of field cap to adapt functionality over life-of-field

Applications

- Meets API 17D and operator requirements

- Up to 10,000ft (3,048m)

- 10,000psi & 15,000 psi applications

Overview

A tree for all phases of field life

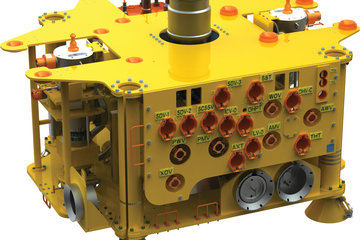

Our revolutionaryAptara™ vertical treeis lightweight and compact, and uses our life-of-field approach to reduce not just initial CAPEX but also OPEX over the entire life of your field. This TOTEX-lite approach features a unique, industry-first, cap design that enables you to adapt the tree on the seabed, as requirements change over the lifetime of your field.

Lower-cost subsea systems

Our simpler, lower-cost vertical subsea systems incorporate 5-inch, and 7-inch production bores, and 10,000 and 15,000 psi pressure ratings, and can be run with or without a tubing-head spool. The Aptara lightweight compact tree can be deployed in up to 10,000 ft (3,048 m) of water.

Life-of-field approach

While the Aptara lightweight compact tree is built on mature, field-proven technology, its design is driven by our life-of-field approach. It uses an innovative flow path that reduces size and complexity, which supports faster field development and lower field total expenditure—so you can maximize value from your reservoir. The configuration has also been simplified, with a lower valve-count that still provides all the functionality you need and complies with all industry standards.

Reduced footprint and weight

The Aptara lightweight compact tree has been designed with the entire lifecycle in mind and our make-to-order variant can be delivered in 10 months. By reducing the number of components, we’ve reduced footprint and weight by around 50% compared with traditional deepwater trees. Reducing size and complexity lowers costs across the entire manufacturing cycle, while the tree’s compact size and reduced weight offer you flexibility during installation and enable vessel optimization. If you want to flow the well, you can also use a subsea test-tree system, either before or after tree installation, as well as a traditional open-water completion-workover riser.

Active control and monitoring

The Aptara lightweight compact tree includes integrated flow metering, incorporating the Baker Hughes distributed flow meter, our SureFLO™ downhole flow meter, and water-cut measurements at the tree. This results in accurate oil, gas and water flow-rate measurements at the wellhead. The system also supports enhanced real-time condition monitoring and diagnostics, enabling active control and monitoring of subsea equipment integrity.

Plug-and-play capability

The Aptara lightweight compact tree system adapts as your needs change through the entire life of your field, with a plug-and-play capability in the innovative modular tree cap that allows your tree system to evolve to suit changing reservoir conditions.

Industry-first design

The unique, patented, industry-first design involves an innovative flow path and tree caps that can integrate functionality such as high-integrity pipeline protection (HIPPS), or add boosting capability to reduce your overall development cost and increase reservoir recovery. The life-of-field tree cap also facilitates conversion of subsea wells from producer to water-injection, adapting your subsea infrastructure to meet reservoir-management needs. Mounting this technology on the tree removes the need for independent modules and connections, reducing your costs further.

Flexibility and functionality

The system is configured for up to 11 downhole functions, including well safety valves, chemical injection, intelligent completions, and two electric functions, adding further flexibility and functionality to improve well performance when installed on a tubing-head spool. The system is configured for up to nine downhole functions when installed directly onto the wellhead. Operations can be optimized with life-of-field tree caps configured for the changing demands of a well’s lifetime.

HIPPS tree cap

The HIPPS tree cap can be added at the start of field life, when pressure is high. This increases your cost efficiency by effectively downrating the subsea pipeline and risers to transient flow pressures. The HIPPS tree cap eliminates the need for the traditional HIPPS module, along with all its associated equipment and installation costs. Additionally, as HIPPS is not required beyond the initial phase, the HIPPS tree cap can be easily swapped for a production tree cap and can be redeployed elsewhere.

Production tree cap

As reservoir pressure falls, or when a HIPPS is not needed, a standard production cap incorporating a choke can be installed.

Boosting tree cap

When boosting is needed in later life of the field, a boosting system can be configured and installed as a tree cap without the need for more equipment on the seabed. This can increase field output and improve the economics of the field.

Features and benefits include:

- Entire life-of-field flexibility

- Innovative flow path enabling installation of HIPPS, production and pumping caps without additional subsea modules through life of field

- Up to 50% reduction in footprint and weight

- Significant reduction in CO2

- 10-month lead time

- Smart real-time monitoring

- TOTEX-lite approach bringing reduced CAPEX and OPEX over entire life of field