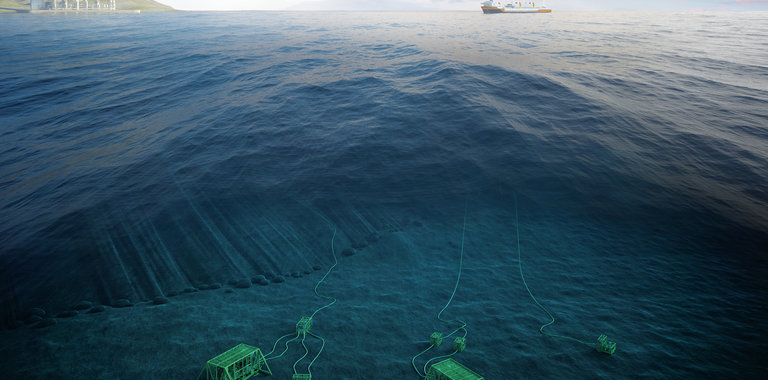

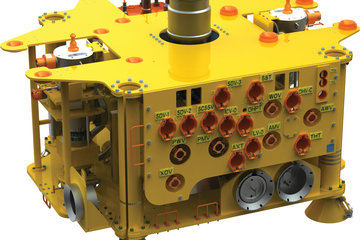

Subsea tree systemsSubsea trees are required to control hydrocarbon production. These complex assemblies of valves and other components are installed at the wellhead to monitor and control production flow, and manage gas or fluids injection. Tree orientations can be either vertical, with production tubing suspended in the wellhead, or horizontal, with production tubing suspended in the tree. Design and materials are determined by operating conditions and the physical environment of each well (key factors include pressure, flow, temperature, and water depth). Standardized and modular designs for consistency and speedBaker Hughes completed its first subsea tree system installation in 1962. Since then, we have installed more than 1,400 subsea trees worldwide and are at the forefront of oil and gas field developments. Our trees are based on standardized, modular designs that drive high manufacturing efficiency and delivery speed. With make-to-order lead times ranging from 10 to 14 months, we can help you minimize the time to first oil or gas, maximizing the returns on your project. Offering both 5-inch and 7-inch systems and up-to 15,000psi pressure rating—in a comprehensive range that includes gas-lift and electrical submersible pumps to maximize reservoir recovery —Baker Hughes has the tree system to meet your needs and facilitate control of intelligent completions in water depths up to 10,000 ft (3,048 m). Features and benefits of our subsea trees include:

Industry-leading valve and connector technologyWe have a strong legacy in key valve and connector technologies, ensuring we deliver trees with the highest levels of reliability and performance. Our latest trees exceed the American Petroleum Institute standard API 17D, and demonstrate our commitment to building systems with industry-leading products. For example, ourVG300valve design, of which there are more than 15,000 in operation, has been successfully tested to 1,200 cycles. This is double the industry-standard requirement and demonstrates the design’s reliability and robustness. Aptara lightweight compact treeDesigned to reduce initial CAPEX as well as OPEX over the entire life of your field, ourAptara™ lightweight compact treeuses an industry-first design. • ~10,000 ft (3,048 m) • 15,000 psi • 300°F (149°C) D-Series for deepwaterOurD-Seriessubsea tree systemstake on the world’s most challenging subsea conditions, with structured, modular, and cost-effective designs and installation. • ~10,000 ft (3,048 m) • 15,000 psi • 300°F (149°C) M-Series for medium waterOurM-Series subsea treesare qualified to meet rigorous international standards for subsea products and use field-proven valves and connectors. • ~2,500 ft (750 m) • 10,000 psi, • 300°F (149°C) S-Series for shallow waterOur light, efficient, and reliableS-series subsea treesfor shallow water are based on an in-depth understanding of the environmental challenges facing operators. • ~330 ft (100 m) • 6,500 psi • 250°F (121°C) Subsea choke valvesOur subsea chokes meet the rigorous demands of your wells and ensure your reservoir performs reliably and safely. Our fast-stepping compact actuator is more than 50% faster than competing products and qualified to two million steps—100% more than industry standards require. This design also enables the use of the Baker HughesElectric Actuator. |

Overview

Get in touch with an expert.

Your request has been submitted.

Thank you for your interest. A specialist will be in touch with you shortly.

Subsea tree systems

4 RESULTS